Energy-efficient hybrid drive and control systems by Rexroth

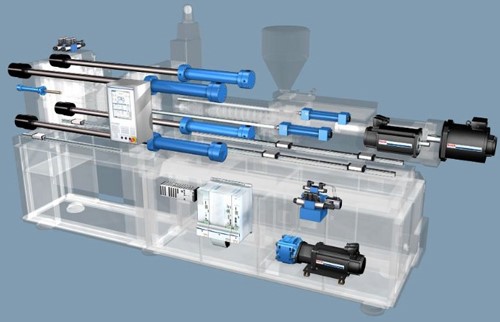

Picture-1 As a provider of cross-technology drive and control solutions, Rexroth has broad experience with plastic processing machines.

In collaborative studies aimed at product development, Rexroth offers highly reliable automation solutions specifically designed for manufacturers of injection molding machines. Rexroth has long years of global experience in the distribution of drive and control solutions for electric, hydraulic and hybrid machines. The hybrid drive system combines the power of hydraulic systems with the electrical drives. The squeezing process in heading die machines is an example of this.

The BlueHydraulics technology reduces energy consumption and noise.

What provides energy efficiency in Rexroth BlueHydraulics plastic injection machines is an eco-friendly modular set. Variable speed drives, and active regulation based on Rexroth BlueHydraulics technology reduce the energy requirement in plastic injection machines by up to 70% and significantly lower noise emissions. In many cases, there is no need to capsulize the hydraulic unit in detail. Active regulation reduces heat transmission to the hydraulic oil, which reduces the investment and maintenance costs of the cooling system. It increases efficiency. Standard fieldbus systems, Ethernet protocols and SERCOS III serve as a communication connection between servo variable pump drives and the high level controller. Drives adapt perfectly to the current automation field because special characteristics of the fluid technology have been integrated in the software. The only the thing the user has to do is configure the first drive parameters.

High-efficiency worm gear drives are compact and durable

Electric motors are not the only solution for worm gear drives. High efficiency hydraulic CA motors by Hägglunds are a valid alternative. These motors have high power density, smooth operation, high reliability and long service life. Because they are highly efficient, they reduce power loss and save space thanks to their compact design. Since their first launch, Hägglunds has been improving Compact CA by increasing rigidity through the finishing characteristics and offering new materials. Hägglunds belongs to Bosch Rexroth since December 2008.

Picture 2 Highly efficient Hägglunds hydraulic CA motors have high power density, a high level of reliability and a long service life.

Hybrid drive systems combine the power of hydraulic systems with electric drives.

The heading die machines, an application that proves Rexroth’s expertise in cross technology, is an example of hybrid drives. As a company based in Berlin, Rexroth developed tailored solutions in partnership with BEKUM. It combines low noise levels, energy efficiency, hydraulic systems and the advantages of electrical drives. A hydraulic transmission reduces the effect of sudden force changes, turning rotational motion into linear motion. Switching point from quick stroke to power stroke can be selected by the user. This way, less tension is created on the elements. Power can be maintained longer without the torque.

Picture 3: Special hybrid solutions: An application that reveals the power of hydraulic systems and compatibility of electrical drives.

Source: Bosch Rexroth Press Release - Advanced Solutions for Plastics Processing Machines (PI 094/10 10/27/2010)